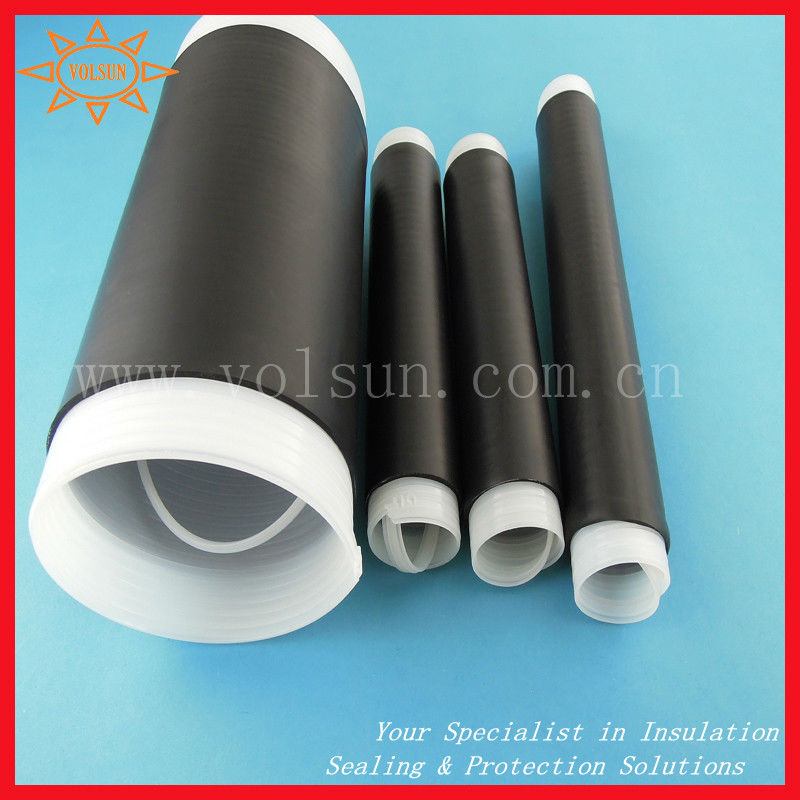

Weather resistance EPDM rubber products

Product Description

High temperature EPDM rubber products

Description

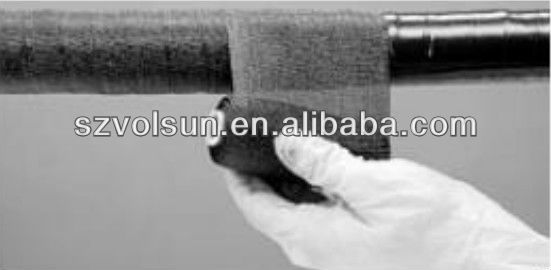

EPDM rubber products. Simply prepare the connection, position the tube and unwind the pre-scored core. The natural tendency of the rubber sleeve to return to its original diameter provides constant radial pressure, forming a reliable, water resistant seal . All without heat, special tools or a time-consuming installation procedure. And, it’s easily removed when system maintenance is required.

Unique Advantages

EPDM rubber products. Excellent weather resistance, ultraviolet aging resistance and higher embrittlement resistance than Heat Shrink Tubing

More resistant to slab and prick, abrasion, acid and alkali than silicone Cold Shrink Tubing

Simultaneously expands and shrinks with workpieces without clearances, seals tight in harsh environment

Stably sealing the workpieces in windy environment

Well suited for cable less than 1KV

Seals tight, retains its resiliency and pressure even after prolonged years of ageing and exposure.

Simple , safe installation, requires no tools or special training. No torches or heat work required.

Diameter shrinkage:≥50%

Standard color:black

Application

Installation features make it the preferred coax connection seal.

Simple installation requires only the installer’s hands.

Excellent weathering properties.

Excellent abrasion resistance.

For protecting feeder connector

High temperature EPDM rubber products can be used for sealing of coax cables with Type N or 7/16 DIN connectors.

Technical Date

Properties | Typical Data | Test method |

HS | 49 A | ASTM D 2240 |

Tensile Strength | 11.8 MPa | GB/T 528 |

Elongation at break | 641% | GB/T 528 |

Tear Strength | 38.6 N/ mm | ASTM D 624 |

Dielectric Strength | 19.1 kV/mm | ASTM D 149 |

Dielectric Constants | 5 | 90°C(in water) 7 days(1940F)5.6 |

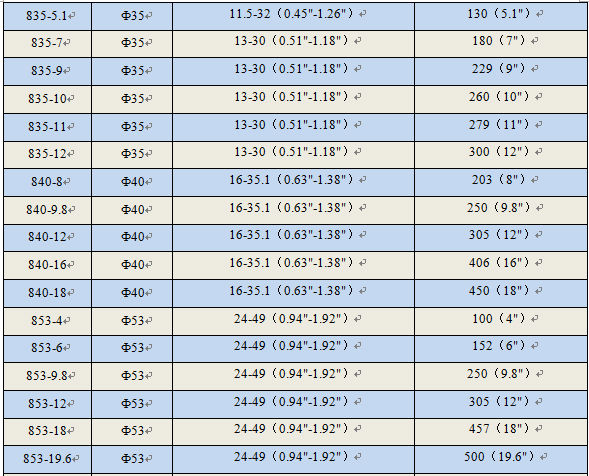

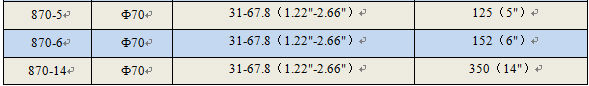

Dimensions

How to use cold Shrink Tube

Quality Control Process

Product Categories : Cold Shrink Tubing

Premium Related Products