Chemical Resistant Viton Insulated 2:1 Heat Shrink Tubing

Product Description

Chemical Resistant Viton Insulated 2:1 Heat Shrink Tubing

Description

TZRS-VT200(2X) 2:1 Heat Shrink Tubing is highly abrasion and cut-through resistant and can withstand a wide variety of fuels, lubricants, acids and highly corrosive fluids at temperatures up to 200°C. In addition to its high continuous operating temperature and chemical-resistance properties, 2:1 Heat Shrink Tubing is very flexible and is easily marked by hot-stamp or printwheel methods. When heated in excess of 175°C (347°F), TZRS-VT200(2X) 2:1 Heat Shrink Tubing rapidly shrinks to a skintight fit. TZRS-VT200(2X) tubing is rated for continuous operation from –55°C (–67°F) to 200°C (392°F).135°C/275°F

Features

Cross-linked fluoroelastomer

Superior abrasion resistance

High temperature resistance

Excellent resistance to aggressive chemicals and slovents

Available with various wall thickness

Continuous operating temperature:-55℃~200℃

Min. Full recovery temp.: 175 ℃

RoHS compliant

Flammability:UL 224 VW-1

Meets: SAE-AMS-DTL-23053/13

Shrink ratio

Modified fluoroelastomer heat shrink tubing has a 2:1 shrink ratio. When freely recovered, the tubing will

shrink to 50% of its as-supplied internal diameter. The recovered wall thickness is proportional to the degree of recovery.

Typical Applications

Because of its outstanding high temperature fluid performance,modified fluoroelastomer heat shrink tubing is often used to protect wiring and component covers in aircraft/aerospace applications including

electronic control systems and hydraulic fluid transport mechanisms and in chemical plants.

Technical Data

Property | Test Method | Typical Data |

|

Property of jacket | |||

Tensile strength | ASTM D 2671 | ≥8.5 MPa |

|

Ultimate elongation | ASTM D 2671 | ≥250% |

|

Heat aging | 250℃, 168 hrs. | ≥8 MPa |

|

Tensile strength | ≥200% |

| |

Ultimate elongation |

| ||

Heat shock | 300℃,4 hrs. | No cracking | |

Flammability | VW-1 | Pass |

|

Volume resistance | IEC 93 | ≥1014Ω .cm |

|

Dielectric strength | ASTM D 2671 | ≥7.9kV/mm |

|

Copper stability | UL 224 | Pass |

|

Copper corrosion | UL 224 | No corrosion |

|

Structure

Dimension

| Size (inch) | Size (mm) | As Supplied (mm) | After Recovery (mm) | Standard Length (m/spool) | |

D* (Min.) | d*(Max.) | w*(Min.) | |||

TZRS-VT200(2X) Fluoroelastomer tubing | |||||

1/8 | 3.2 | 3.2 | 1.6 | 0.80 | 100 |

3/16 | 4.8 | 4.8 | 2.4 | 0.95 | 100 |

1/4 | 6.4 | 6.4 | 3.2 | 0.98 | 50 |

3/8 | 9.5 | 9.5 | 4.8 | 1.00 | 50 |

1/2 | 12.7 | 12.7 | 6.4 | 1.16 | 30 |

3/4 | 19.1 | 19.1 | 9.5 | 1.49 | 30 |

1 | 25.4 | 25.4 | 12.7 | 1.85 | 30 |

1 1/2 | 38.1 | 38.1 | 19.1 | 2.10 | 15 |

2 | 50.8 | 50.8 | 25.4 | 2.10 | 15 |

TZRS-VT200(2X) Thin wall fluoroelastomer tubing | |||||

3/8 | 9.5 | 9.5 | 4.8 | 1.00 | 50 |

1/2 | 12.7 | 12.7 | 6.4 | 1.00 | 30 |

5/8 | 15.9 | 15.9 | 7.9 | 1.20 | 30 |

3/4 | 19.1 | 19.1 | 9.5 | 1.25 | 30 |

7/8 | 22.0 | 22.0 | 11.0 | 1.37 | 30 |

1 | 25.4 | 25.4 | 12.7 | 1.37 | 30 |

1 1/4 | 31.8 | 31.8 | 15.7 | 1.54 | 30 |

1 1/2 | 38.1 | 38.1 | 19.0 | 1.54 | 15 |

2 | 50.8 | 50.8 | 25.4 | 1.82 | 15 |

Note:

D* = Inner diameter as supplied

d* = Inner diameter after fully recovered

w*= Wall thickness after fully recovered

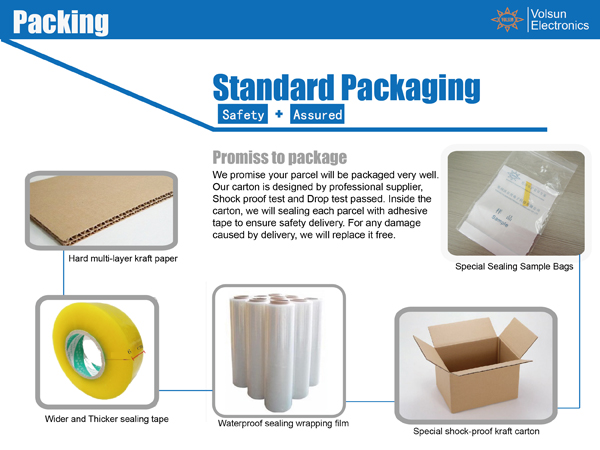

Package Information

SGS Certification

Company show

They trust us

Contact us if you need more details on 21 Heat Shrink Tubing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Chemical Resistant 21 Heat Shrink Tubing、Viton 21 Heat Shrink Tubing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Special Material Heat Shrink Tubing

Premium Related Products